Gmp Approval. GMP meaning the basic regulation promulgated by the US Food and Drug Administration (FDA) under the authority of the Federal Food, Drug, and Cosmetic Act to ensure that manufacturers are taking proactive steps to guarantee their products are safe and effective. cGMP, on the other hand, was implemented by the FDA to ensure continuous improvement. Detailed written procedures are essential for each process that could affect the quality of the finished product. Is GMP necessary if there is a quality control laboratory? GMP regulations address issues including record keeping, personnel qualifications, sanitation, cleanliness, equipment verification, process validation, and complaint handling. GMP covers all aspects of production from the starting materials, premises, and equipment to the training and personal hygiene of staff. FDA assessors and investigators determine whether the firm.

Gmp Approval. FDA approval for the same indication to commence Phase I/II clinical trials. Fusion Gun, Man-Portable (science fiction, gaming) FGMP. Good Manufacturing Practice (GMP) is a quality management system that describes a set of principles and procedures that ensures the products are consistently produced and controlled according to preset quality standards and criteria. The main regulatory standard for ensuring pharmaceutical quality is the Current Good Manufacturing Practice (CGMP) regulations for human pharmaceuticals. Is GMP necessary if there is a quality control laboratory? First, we must consider the project needs and necessary steps for getting your new facility FDA-GMP, or EU GMP approval. Gmp Approval.

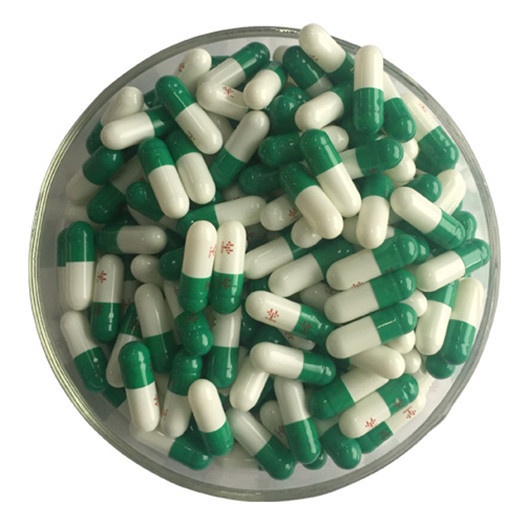

A code of standards concerning the manufacture, processing, packing, release and holding of a medicine.

Good manufacturing practice (GMP) is the minimum standard that a medicines manufacturer must meet in their production processes.

Gmp Approval. Direction Générale des Marchés Publics (French: General Directorate of Procurement; Burkina Faso) DGMP. The main regulatory standard for ensuring pharmaceutical quality is the Current Good Manufacturing Practice (CGMP) regulations for human pharmaceuticals. This starts from the beginning when choosing a location, and then. GMP regulations address issues including record keeping, personnel qualifications, sanitation, cleanliness, equipment verification, process validation, and complaint handling. GMP meaning the basic regulation promulgated by the US Food and Drug Administration (FDA) under the authority of the Federal Food, Drug, and Cosmetic Act to ensure that manufacturers are taking proactive steps to guarantee their products are safe and effective. cGMP, on the other hand, was implemented by the FDA to ensure continuous improvement. FDA assessors and investigators determine whether the firm.

Gmp Approval.